September 24, 2023

I’m finally back to working on the layout and posting. A lot of August entailed preparing clinics and the layout for the National NMRA convention. Immediately after my wife had her knee replaced. Caring for her the first 2 weeks was a full time job. I’m happy to report that she is now walking without any assistance. Still can’t bend down very well, but I’m hoping she will be able to take over some of the cooking. I do have to take her to PT 3 times a week for the next couple of months until she is off pain meds and can operate brake in the car.

I’ve gone thru all of Gerber Yard with a track gauge checking every switch even though a test car with code 88 wheelsets had no problem. Since I am all steam, I wanted to make sure everything was spot on. Pilot wheels and trailing trucks can be very troublesome. There were some places where switches were just a little tight after the points (mainly the #8’s.) I also discovered a couple of places where code 70 rail was on top of a rail joiner and one solder failure.

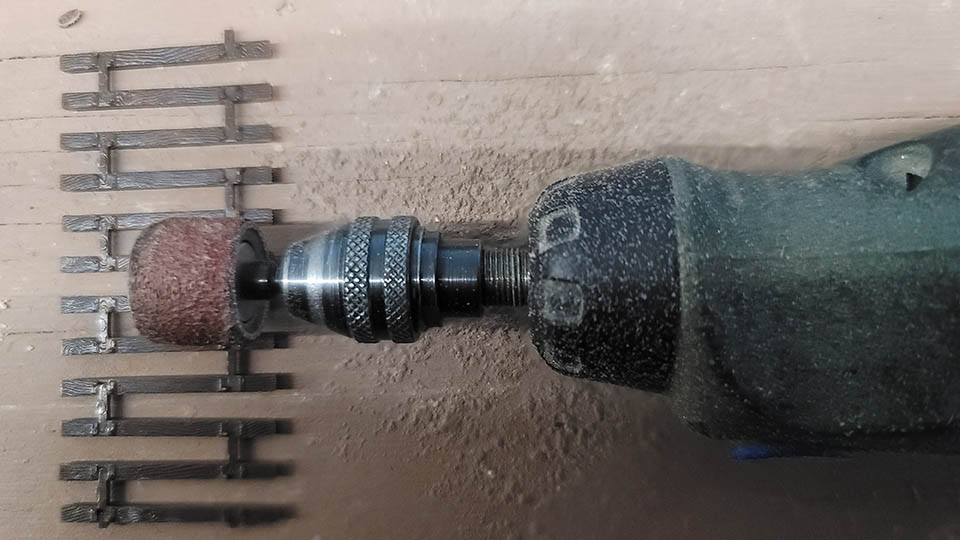

Ties have been added under all rail joints. Wooden ties were used in most places. If clearance was tight, a sanded off plastic tie was used. The example attached has both. Carpenter’s glue was dabbed on to make sure they did not move during ballasting.

A spur by the station was too far to reach, so I installed an undertrack magnet. A white tube of latex was accidently used to hold down track. It really does not matter after ballasting. Another magnet will be added between the ties on the passing track just above the spur.