June 2, 2023

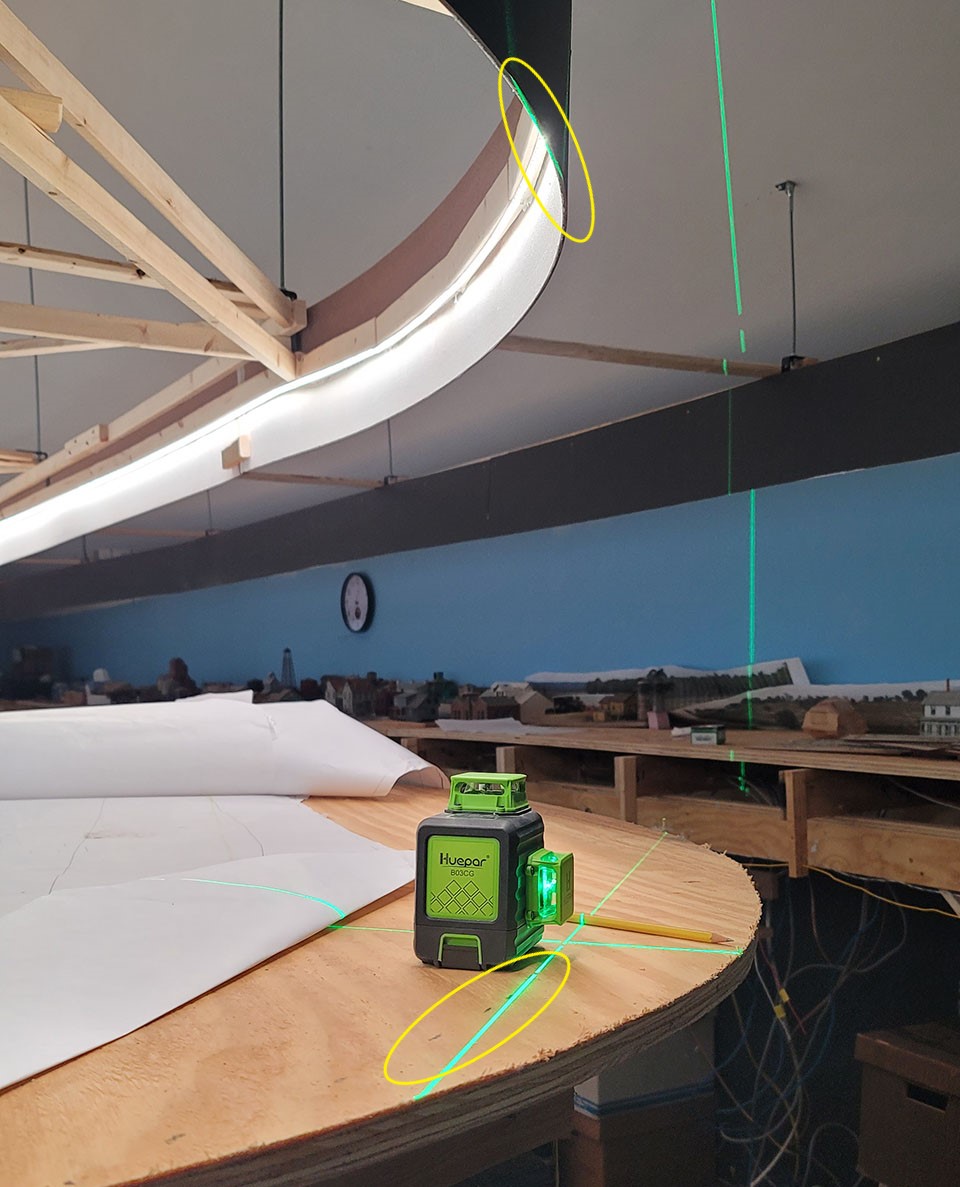

I’m back to work after a 10 day break with visitors and car shopping. First project was to trim plywood and screw it in place. My laser came in handy to mark the edge of the layout which coincides with the valence. The laser is moved until it just hits the edge of the valance and then a dash is made for the cut line. Moving it a few inches at a time soon gave me the curve that was needed.

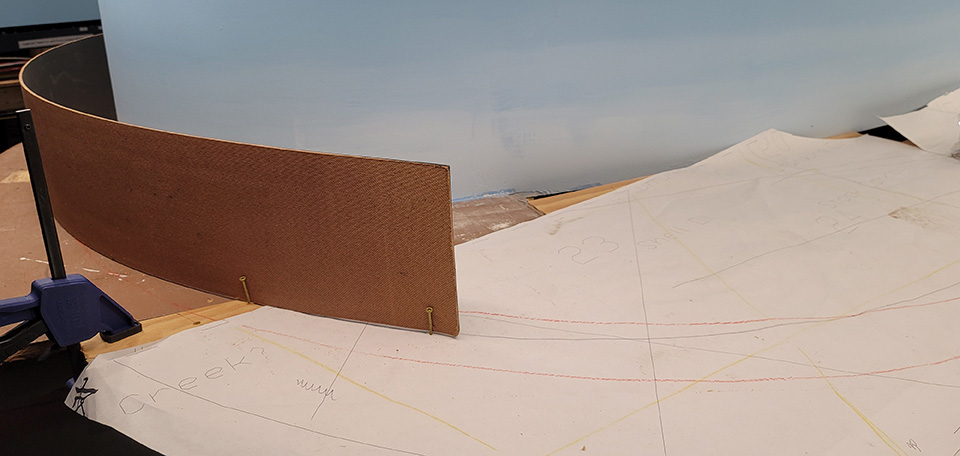

The Red Bluff full size plan was unrolled. A smooth curve was needed to continue around the dispatcher duck-under. A piece of plywood that had a little larger radius was used as a pattern to give a rough idea of the location. The curve on the plan was continued using a piece of hardboard.

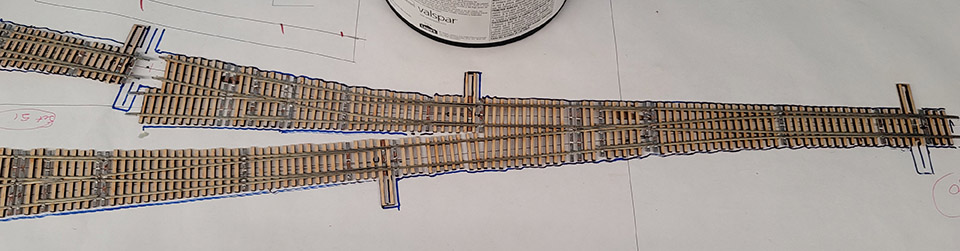

Small slits were cut in the plan to a marker to outline the outside of the yard area. Two sets of 3 switches were soldered together on the paper plan. By making the switches as sets, far fewer rail joiners are used and the track flows better.

This time Midwest flat cork sheets were used rather than the roll cork in Gerber. Much easier to work with. Roadbed profiles were added to the edges. Tomorrow track will be added, and the cork extended to cover more of Red Bluff.